Running an omnichannel business is serious work.

The more channels you use, the more important it is to have a watertight system that puts every piece in its right place.

- Have you accounted for customer returns and optimized your safety stock so you’re not operating at a loss?

- Does your inventory management software sync orders between physical locations, your website, and your Amazon store?

- What about in-store pickup for online orders or home delivery for an item that wasn’t in stock in your store?

Sadly, the average retailer only has 63% inventory accuracy.

Let’s go over some of the key drivers of this, and how you can suit up to protect your brand from falling victim.

Don't have time to read the full article? We brought in the experts from Deloitte, 6 River Systems, and UPS to share best practices for supply chain and logistics management during a pandemic in our latest webinar. Save your seat.

Common barriers to omnichannel inventory optimization

As a business expands its empire into omnichannel, there are some “growing pains” that are commonly seen. From your supply chain to your returns process, these issues can either creep up slowly or hit you like a freight train—depending on how fast you’ve grown.

Here are a few of the top obstacles.

Segmented supply chain processes

This one is a killer. Say you have a successful brick-and-mortar location and you’ve just added your online storefront to the mix. If you don’t condense into a single system, you might encounter a lack of inventory visibility across channels and segmented supply chain processes.

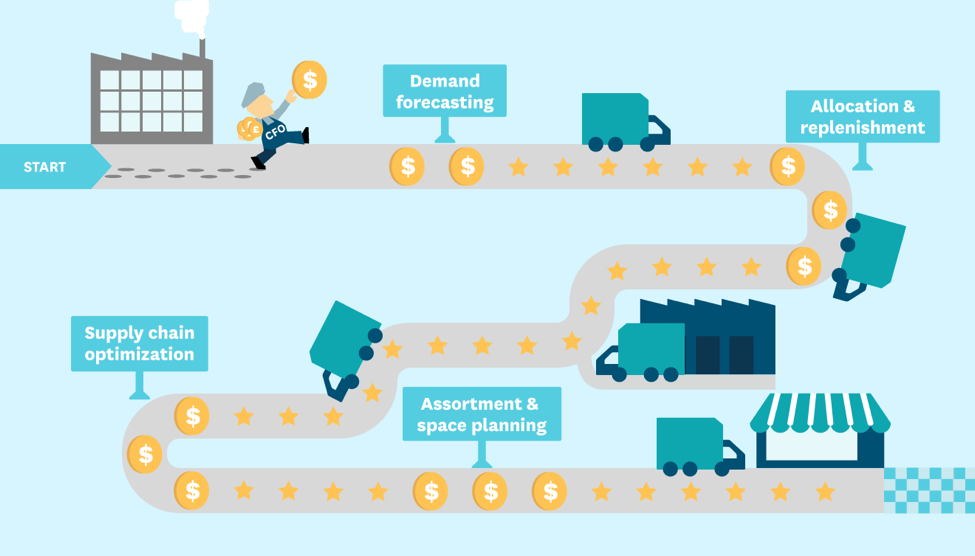

It’s easy to miss one or more steps of the supply chain process, like demand forecasting, allocation and replenishment, supply chain optimization, and assortment and space planning.

A gap in your supply chain can be the culprit for basically any issue you might encounter during the order fulfillment process – from delayed delivery to customers ordering stocked-out items.

This is especially true in an age where customers hold all the power with demands for instant quality, which strains suppliers to deliver top value at bottom costs.

Bloomberg Businessweek reports that 73% of companies are aware of the importance of supply chain tools when it comes to meeting their company goals, but many still fall short.

As Digitalist Mag puts it:

Traditional supply chain tools cannot keep pace with the digital modern commercial landscape. And they certainly can’t keep you competitive.

Growing companies will need to be proactive in their search to find the right solution for their brand.

Too much money invested in safety stocks

In the inventory management realm, safety stocks are a tricky topic. Depending on the circumstance, stockouts can be a devastating blow for companies. So it’s natural for companies to put some elbow grease into stock management.

But how much is too much preparation?

You’ll find a number of theories for how different companies set their safety stock levels. You’ll also find an equal number of pitfalls in their planning, ranging from miscalculations to unforeseen spikes and valleys in demand and lead times.

And then there’s the lost revenue from items that aren’t sold with their brethren, leading companies to a number of tactics to scrape the barrel for what they can get, like selling them off at clearance prices, bundling them with more “relevant” products, donating them, or returning them to the supplier.

For many, finding the sweet spot of safety stocks can feel like a never-ending battle.

Learn more: Omnichannel retailing simplified

Single-echelon inventory control

Single-echelon (single-tier) vs. multi-echelon (multiple-tier) inventory optimization is an important concept to manage as your omnichannel empire grows.

To put it simply, single-echelon inventory control focuses on inventory management for an individual unit of your supply chain network. Multi-echelon inventory control and optimization are more holistic approaches that focus on inventory levels across the entire network.

Smaller companies naturally operate on a single-echelon model. This is especially true if you only have one distribution center (DC) that lives at the center of your fulfillment system. In that setting, inventory management is linear, and complexity, low.

But as you grow, more pieces are added to the puzzle. Once you start adding multiple DCs, you may need a central or regional distribution center (RDC) that suppliers send items to, which are then sent to your DCs.

Take for example a major retailer that has thousands of locations — they may have 10 RDCs that ship to 50,000 DCs.

For a budding omnichannel company, a single-echelon system that once worked flawlessly can easily become a cobweb of patches and workarounds, clouding inventory visibility and preventing smooth fulfillment across the entire business.

Fragmented reverse logistics

Returns are important. They instill confidence in your customer that you stand behind your products and you’re committed to keeping them happy.

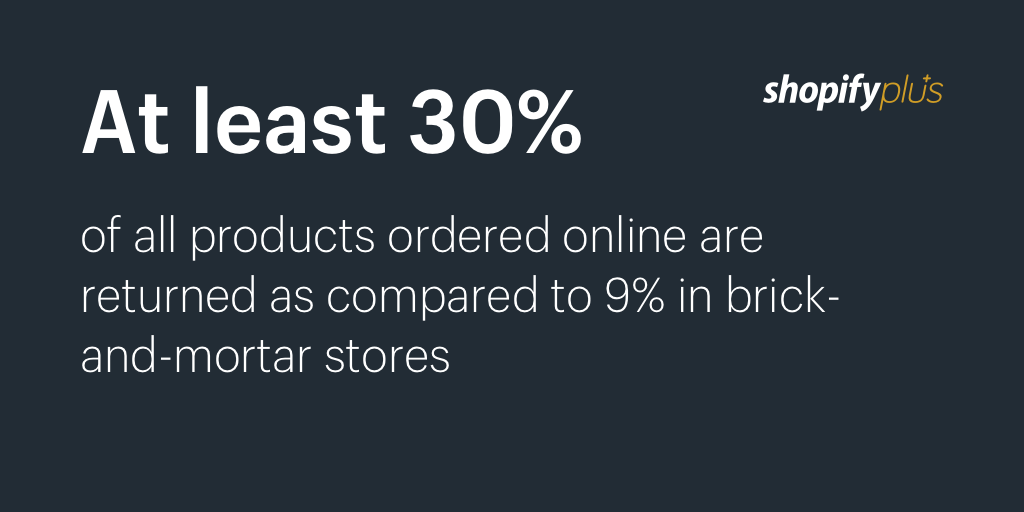

Invesp found that roughly 30% of online-ordered products are returned, in comparison to nearly 9% for brick-and-mortar purchases. If you’re selling on both channels, you’ll be interested to know that 62% of surveyed shoppers said they’re more likely to order online when they have the ability to return the item in-store.

While strong returns are all but mandatory in today’s retail landscape, they can gum up the works for your inventory management process—more so for omnichannel retailers, and exponentially so for omnichannel retailers that allow items to be returned to a different location than where they were purchased, like online to a brick-and-mortar store.

There are the extra costs of labor for your in-house employees or third-party partners to collect, evaluate, and sort them. Then they’ll need to decide whether each item will be put back on the shelf, sold to a clearance reseller, recycled, or possibly returned to the distribution center for refurbishing, cleaning, or repackaging.

Because returns are a hot-button topic that’s growing into a requirement, retailers are hesitant to recoup these costs by charging for return shipping.

In a survey by DC Velocity, only 30% of retailers said they charge customers for returns shipping to recover these supply chain costs and 20% charge fees for processing them. To add insult to injury, less than half can even measure the financial impact that returns have on their company.

The bottom line is it’s an inevitable and pricey process, so you’ll need a strong system in place to minimize the drain of your resources.

Tactics to solve optimization challenges

Call it Newton’s third law of ecommerce: for every inventory optimization challenge, there’s an equal and opposite inventory optimization solution.

Integrated supply chain

Deloitte reports that 78% of businesses with high-performing supply chains have more revenue growth than their industry counterparts.

The key to solving this issue is in your software – you’ll want to implement an optimized warehouse management system (WMS) or inventory management system (IMS).

The idea is to have crystal-clear inventory visibility across all channels, which you can use as a forecaster of future product demand. And when order management and fulfillment operations are synced up in real-time across channels, each order can automatically trigger the closest distribution center and the most efficient in-house or third-party fulfillment entity.

Take it from Original Grain, a Shopify customer that recognized early on addressing the challenges of omnichannel would be the backbone of the company. This mentality allowed them to sail past the eight-figure mark within four years, selling across multiple channels including brick-and-mortar, their Shopify store, and Amazon.

Reducing safety stock

If you’re losing too much money in your safety stock game, recovery comes from calculations and tracking.

Be warned that, generally speaking, you can dive down a serious rabbit hole when it comes to the art and science of calculating.

But any formula you encounter will ultimately take into account your product’s demand and its lead time.

Here’s a more common, simple safety stock formula template:

Safety stock = (Maximum Daily Usage x Maximum Lead Time) - (Average Daily Usage x Average Lead Time)

Say that you’re a clothing retailer looking to optimize your best-selling sports jacket. You average 8 per day, but during winter, you can sell 15. The average lead time from your international supplier is 24 days. But you recall that during Chinese New Year last February, your supplier was closed for a week, which bumped lead time up to 31 days.

You’re looking at:

(15 x 31) – (8 x 24) = 273 sports jackets in your safety stock around Chinese New Year

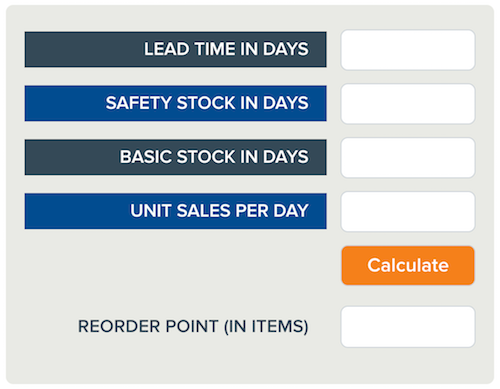

Also to consider is the optimal reorder point, which you can examine with this handy calculator.

It’s important to remember that your optimal safety stock will rarely be steady, so you’ll want to make sure that your system is continuously monitored and adjusted when needed, especially to accommodate seasonal and promotional changes in demand and service capabilities.

Learn more: Get omnichannel marketing ideas to connect with customers—without being creepy.

Multi-echelon inventory optimization

When you’ve got multiple echelons, you’ve got to embrace a multi-echelon system. Multi-echelon inventory optimization (MEIO) fosters interoperability between all layers of your supply chain and distribution network.

MEIO helps to refine your safety stocks across your whole supply chain, accounting for all of the interdependencies between each stage. It also examines the variables that can lead to excess inventory, including uncertainty in demand, volatility in supply, and long lead times.

This model optimizes based on key inventory drivers that include replenishment frequency, order supply strategy, and your service level goal. These inventory drivers are optimized on a wide-scale, enterprise level as opposed to piece-by-piece, like what would happen if you used a single-echelon approach for a multi-echelon company.

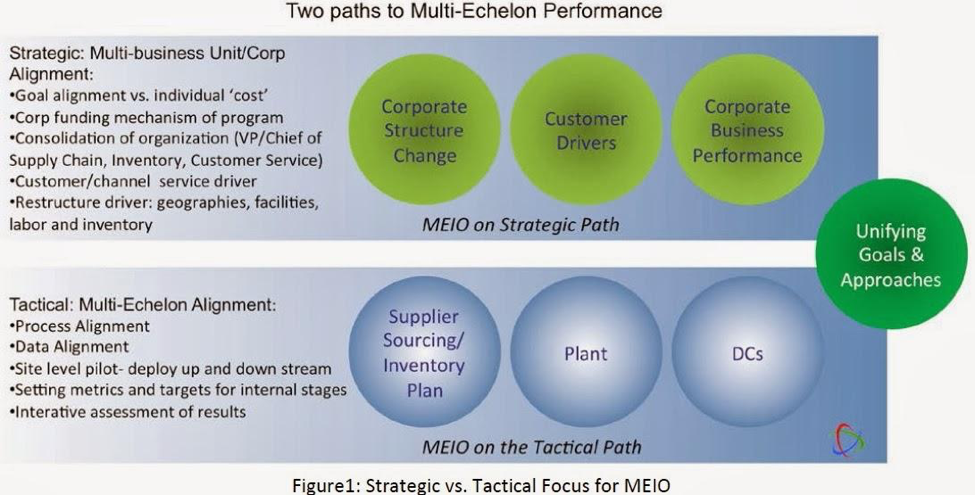

There are two main paths to reaching multi-echelon performance: the strategic and the tactical path.

The strategic path involves consolidating and re-structuring the company based on geographies, facilities, labor, and inventory. The tactical path involves aligning your systems, processes, and data with metrics and targets for each stage.

If you’re interested in learning more about this inventory management strategy, there are plenty of solutions offering specialized MEIO, like Logility and Llamasoft.

Improving reverse logistics

Thankfully, there are a lot of tools and systems that can help build a more efficient and profitable (or at least less unprofitable) returns process.

Here are a few key reverse logistics strategies to consider:

- Having a streamlined repackaging process

- Creating a clear customer-facing return policy

- Considering the help of a third-party logistics (3PL) company to manage and optimize the process

While it may seem like more of a hassle than a benefit, make sure you view returns through the lens of customer service. To put it frankly: flexibility and transparency create trust, which leads to higher purchase values, loyal customers, and better long-term business.

Consider Zappos, which was among the first companies to offer a free two-way shipping, 365-day return policy on shoes. They were practically begging for returns. What they found was that the customers who bought the most expensive shoes returned about 50% of purchases.

At first glance, you might reflexively say “ouch.”

But they made higher profit margins because the shoe costs surpassed the shipping costs. So in the end, the customers with the most returns became their happiest and most profitable customers … because of the returns.

As Craig Adkins, VP of Services and Operations at Zappos, explains:

Our best customers have the highest return rates, but they are also the ones that spend the most money with us and are our most profitable customers.

Obviously, this strategy won’t work for everyone, but it’s important that you never underestimate the power of a happy customer.

Optimize, refine, profit

Poor inventory management is a massive cause of financial loss for omnichannel companies, and it can be a make-or-break in our highly competitive, customer-centric shopping landscape.

One reason there are successful omnichannel examples is a proactive inventory system that works for you instead of you reactively working for it. It may seem overwhelming, but there are tools and systems to help.

Business owners who optimize their inventory management can attest to having more satisfied customers and higher revenue while experiencing fewer complications and fewer fires to put out.

With a strong system, you can rest easy and turn your Spidey sense off high alert.

Read more

- How Ecommerce Teams Get Buy-in To Sell More

- The Science of Impulse Purchases: How to Encourage Your Customers to Buy More on the Fly

- Supply Chain Optimization: How to Develop a World-Class Logistics Network

- Gift Wrapping in Ecommerce: How to Boost AOV This Holiday Season

- Shopify Flow Templates you can use During COVID-19

- New Ecommerce Visitors: How to Serve Up Their Hidden Desires and Pull 'Em into Your Online Funnel

- Customer Retention: How to Turn New Shoppers into Repeat Customers

- How to Personalize for Unknown Black Friday Cyber Monday Mobile Visitors

- How to Monetize Dormant Customers With a Successful Winback Campaign

- SEO Product Descriptions: 7 Tips To Optimize Your Product Pages for Search